However, it is not uncommon to find sites using a compressor first installed 30 or 40 years ago. When capital investment needs to be considered carefully a seemingly reliable machine is unlikely to be high on the list of equipment replacement priorities, even if it is not performing as well as it could be

The new guide therefore examines some of the areas to consider when specifying a new machine, with the latest, rotary vane technology proposed as an ideal option.

The Hydrovane Air Solution is one such solution. Its rotatory vane technology comes complete with all the required ancillaries to produce clean, dry air - air receiver, dryer and filtration - in one compact unit, to save on installation time and cost.

Models are available from 4kW to 22kW in both fixed and regulated speeds, with automatic start/stop, low noise levels, dry air and filtration down to 0.01 micron. Designed and manufactured in the UK, the machine offers a market-leading 10-year extended warranty programme designed to deliver comprehensive warranty cover for up to 10 years or 48,000 operating hours.

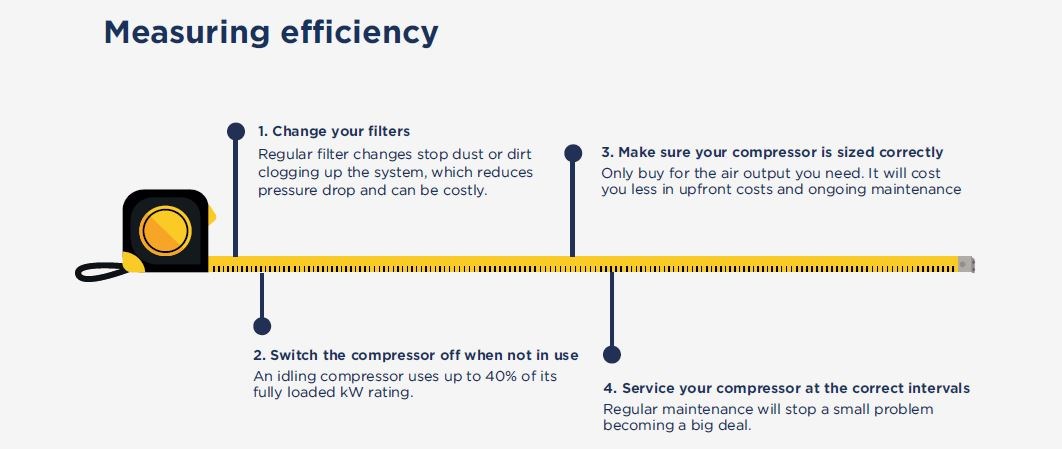

Steve Downes, Hydrovane Sales Manager at Gardner Denver, said: "We have created this guide to provide practical advice to those whose businesses depend on reliable and efficient compressed air. The tips it offers on maintenance and spare parts could help prevent a small problem becoming a major cause of downtime, so companies can continue to get the best out of their compressor

"To that end, we would encourage all operators to choose a compressor that best suits their level of demand. In the case of smaller business owners, we would advise they take a look at rotary vane technology, as it provides reliability, efficiency, and quality on a more appropriate scale to their needs."

For more information on the Hydrovane Air Solution, Gardner Denver's 'plug-and-play' rotary vane technology system, please Contact Us.

Global (EN)

Global (EN)