Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

USA (EN)

USA (EN)

- ARTICLES

- All Articles

- Compressed Air Overview

How can we help you?

Compressed air is accurately known as the phantom utility. Unlike gas, water and electricity, compressed air is not supplied from outside sources and charged to you by a meter. You can't buy compressed air; you have to produce it yourself. The challenge is to produce this important utility as effectively and efficiently as possible, despite the fact that compressed air is not your primary business.

Compressed air deserves special attention. When properly applied, compressed air is a labor-saving utility that increases production output. About 10% of all electricity in industry is used to drive compressors, and with ever-rising utility rates and the trend toward lower levels of manpower in maintenance, selecting an efficient, reliable air compressor is paramount.

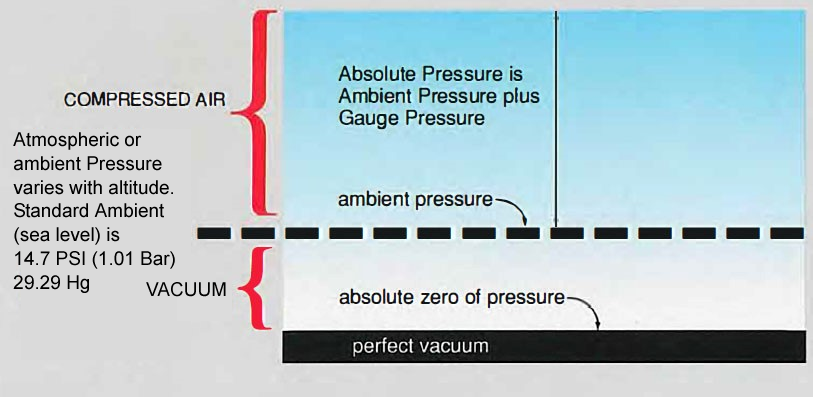

The sea of air that surrounds the earth, called atmosphere, exerts pressure on everything around us. Atmospheric air pressure varies with elevation and temperature. Air at atmospheric conditions is generally called "free air."

Compressed air is free air that has been forced into a smaller volume and is now at a pressure greater than atmospheric.

Compressed air is expressed in terms of pressure and volume.

Pressure is measured in Pascal (Pa) which is equivalent to one Newton per square meter (N/m2) or the KiloPascal (kPa) where 1 kPa = 1000 Pa.

The majority of industrial air applications require a pressure level between 7 and 12 Bar.

The volume or amount of compressed air per unit of time that a compressor can produce is measured in cubic meters of air per second (m3/s).

The capacity of an air compressor is its ability to deliver a volume of air at an absolute pressure.

When comparing compressor performance, be certain the volume of air is expressed in similar terms.

The volume of air a compressor delivers depends upon the actual temperature and pressure of the inlet air.

When comparing the air delivery of compressors, know the temperature and pressure of the inlet air.

Actual CFM (ACFM) or Inlet CFM (ICFM) - Air delivery measured at the actual temperature and pressure conditions of the inlet air. The pressure and temperature readings are usually taken just outside the inlet air filter.

Standard CFM (SCFM) - Air delivery at standard conditions. In the compressed air industry the conditions are usually 14.7 PSIA and 68°F.

Rule of Thumb – As pressure increases, the volume decreases, and vice versa.

Compressed air is stored energy that does work when it is released. You are familiar with several forms of compressed air.

| |

|

|

| Tire Pump | Spray Paint | Pneumatic-Operated Tools |

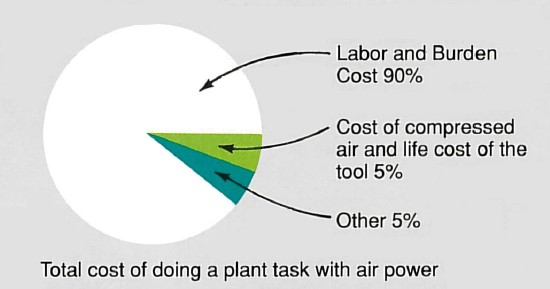

The cost of compressed air and the tool itself are usually insignificant compared to the savings and productivity increase realized by its use.

Since labor is the largest cost component, a compressor with excess capacity is far less costly than an inadequately sized compressor with subsequent loss of productivity.

Compressed air as a utility offers several advantages over other energy sources.

Energy expense is the major cost in the production of compressed air. Electrical expense for a two-shift operation of a new compressor will exceed initial purchase price of the compressor in the first year of operation.

Some compressors are more efficient than others. The energy expense savings can be substantial and must be evaluated.

Dynamic Compressors: Air is compressed by the dynamic action of rotating impellers or vanes imparting velocity and pressure to the gas.

Centrifugal: A centrifugal unit compresses air by the mechanical action of a rotating impeller that imparts velocity and pressure to the air, raising it to the required discharge pressure.

Positive Displacement Compressors: Successive volumes of air are confined within a closed space where pressure is increased as the volume of the closed space is decreased.

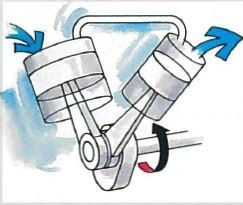

Reciprocating: Reciprocating compressors may be either single-stage or two-stage (multi-stage). Each type may be single- or doubleacting.

Single-stage: Air is compressed from atmospheric pressure to discharge pressure in one step or stage.

Two-stage (multi-stage): lnlet air is compressed to an intermediate pressure in the first stage, then cooled by an intercooler and compressed to a higher pressure in succeeding stages, until the final discharge pressure is attained. Two- or multiple-stage compressors are generally used for higher pressure applications.

Single-acting: Air is compressed only on the upstroke of the piston.

Double-acting: Air is compressed on both the upstroke and down stroke of the piston.

Rotary: Rotary compressors are another type of positive displacement compressor.

Rotary Screw: Once air enters a rotary screw compressor, it is trapped between mating male and female rotors, and compressed to the required discharge pressure.

Sliding Vane: Air is trapped by vanes that slide radially by centrifugal force. The trapped air is compressed as the volume decreases due to the rotating cylinder being offset in the housing.

Determining volume requirements will help narrow down the number of potential compressor choices.