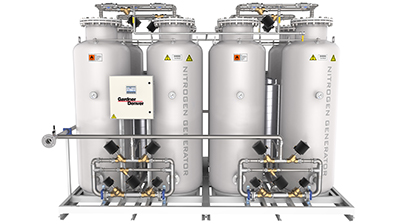

Gardner Denver’s Pressure Swing Adsorption (PSA) nitrogen generators eliminate the need for traditional nitrogen shipments and storage, providing you with real cost savings. Our on-site nitrogen generators offer a variety of innovative solutions that are customizable to meet your production needs. They can also reduce operating costs when compared to a traditional nitrogen supply. After a year of utilizing a Gardner Denver nitrogen generator, you will find incredible savings.

10-20% of bulk nitrogen is typically wasted from bleed off or failure to extract all of the product. Gardner Denver’s PSA technology reduces waste and operates sustainably. With access to our entire portfolio of related products and services, you’ll have a trusted partner for nitrogen solutions from start to finish.

Benefits of Gardner Denver Nitrogen Generators

Gardner Denver nitrogen generator systems with innovative solutions are robust and rugged, offering the following benefits:

· Reduce operating costs by generating nitrogen onsite from available air

· Air-to-nitrogen utilization maximizes system energy efficiency

· Nitrogen purity to meet your requirements

· Sustainable operation, minimal waste

· Eliminate the safety and footprint issues associated with traditional nitrogen storage

Built-in Safety

Gardner Denver PSA nitrogen generators come pre-assembled and factory tested for easy plug-and-play installation.

· High quality CMS media extends product life and lowers total cost of ownership

· Long-life valves control gas flow with quick, precise switching to improve durability and efficiency

· Controls optimize set points and offer system protection

Industries/Applications

Industries such as food and beverage, electronics, petrochemical, pharmaceutical and metal operations rely on nitrogen for their manufacturing processes. Readily available in the air that we breathe, nitrogen is one of the most economical inert gasses. When used in industrial processes nitrogen can help avoid combustion, corrosion and product spoilage, and is widely used in food packaging to the prolong the life of the contents which will remain fresher for longer.

Nitrogen plays an important role in the food and beverage industry. Nitrogen allows for efficient, economical preservation used for both transportation and storage of food and beverage products.

Compressed air is filtered through the membrane to produce nitrogen. The nitrogen is then used to replace oxygen during food packaging to preserve freshness and dry glass bottles before filling. Nitrogen generators reduce operating expenses and simplify food and beverage operations.

Global (EN)

Global (EN)