Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

- Industries and applications

- Clean Air and Vacuum

How can we help you?

Choose a different country or region to see the content specific to your location

Current Region:

Global (EN)

Global (EN)

How can we help you?

With today’s need for critical clean air & vacuum, superior air quality, equipment reliability, and environmental awareness are key components when specifying a system. There is only one company that offers the essential technologies and support to meet the demanding requirements of hospitals and laboratories. Combining over 160 years of global experience with an unmatched authorized local distribution network, Gardner Denver delivers professional guidance to ensure your facility conforms to the most recent related codes. Gardner Denver specializes in environmentally aware markets by manufacturing NFPA and CSA Code compliant medical air and vacuum systems.

Packaged compressed air systems are installed as central systems in hospitals and are piped to distribute compressed air to different parts of the facility. Compressed air is used for numerous patient care applications – from keeping patients comfortable and breathing to the operation and performance of handheld medical tools and devices. These systems are packaged with air dryers, monitors and controls in order to be compliant with the NFPA-99 code. This health care facilities code establishes criteria for levels of health care services or systems based on risk to the patients, staff, or visitors in health care facilities to minimize the hazards of fire, explosion and electricity.

Oil-Free and Oil-Less Air Compressors

Compressed air systems in hospitals need to supply clean, dry compressed air with a high level of reliability. Gardner Denver incorporates innovative oil-free and oil-less compressor technologies as the core of the system design. Read more about our oil-free and oil-less compressed air product offering here:

Advantages of our Oil-Free and Oil-Less Compressors:

During surgical procedures, the patient is administered a mixture of anesthesia gases and a high concentration of oxygen. This gas mixture is inhaled by the patient and then exhaled. The exhaled gases need to be suctioned away so they do not vent into the operating room. This removal process is what is termed as WAGD (Waste Anesthetic Gas Disposal) and a vacuum pump is utilized to provide the necessary suction flow.

Oxygen Rated Claw Vacuum Pumps

Oxygen rated claw vacuum pumps offer the most efficient, clean and safe way to suction away waste anesthetic and oxygen rich gases from the patient during a surgical procedure. Standard vacuum pumps, which contain hydrocarbons from petroleum products inside the pump, can present the risk of a fire or possible violent reaction when high concentration levels of oxygen are present inside the pump. The Gardner Denver “OXY” claw pumps provide the highest level of safety and performance.

Advantages of our Oxygen Rated Claw vacuum pumps:

Oxygen concentrators generate necessary gases on site. An oxygen concentrator uses the surrounding atmosphere to create oxygen-rich air by pulling air into the oxygen machine, compressing it, purifying it and removing nitrogen and other impurities. The purified, oxygen-rich air is then delivered to the patient. Oxygen concentrators require an efficient compressor that can achieve high pressure and flow and low power consumption. They also require an efficient vacuum pump to separate the nitrogen from the oxygen.

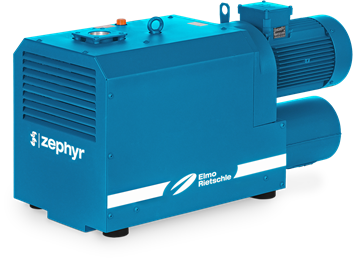

Oil Lubricated Rotary Vane Vacuum Pumps

Our compact VC vacuum pumps are known for their low noise and reliability which make them an ideal choice for oxygen concentration applications within hospitals.

Advantages of our Oil Lubricated Rotary Vane Vacuum Pumps:

Mattress systems combine multiple therapies with advanced algorithms to determine and display therapeutic support pressures, based on each patient’s specific height and weight. Precise cyclic loading and off- loading provides maximum differentiation between the inflated and deflated cells. The result is superior pressure redistribution across the entire body of the patient and the prevention or cure of pressure ulcers commonly called bedsores.

A ventilator is a device that is designed to provide mechanical ventilation for patients who need support to breath or cannot breathe on their own. Ventilators have a small blower component which provides air flow moving breathable air via a mechanical pumping operation into and out of the patient's lungs. They are used across healthcare including intensive care units (ICU), at home and in transit during emergency medical care at accident sites or in transit to a medical facility.

Regenerative Blowers

Regenerative blowers offer compact and quiet air supply for medical ventilators and hospital beds. Specifically the 2BH100 - with a height and width of approximately 4.9 inches and a depth of approximately 2.4 inches, the 2BH100 blowers are the smallest regenerative blowers available on the market. They are easy to install and extremely compact and quiet – perfect for use in close proximity to a patient.

Advantages of our Regenerative Blowers: