Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Poland (PL)

Poland (PL)

- transport

- Pompy do transferu cieczy

- SSP Seria S

Choose a different country or region to see the content specific to your location

Current Region:

Poland (PL)

Poland (PL)

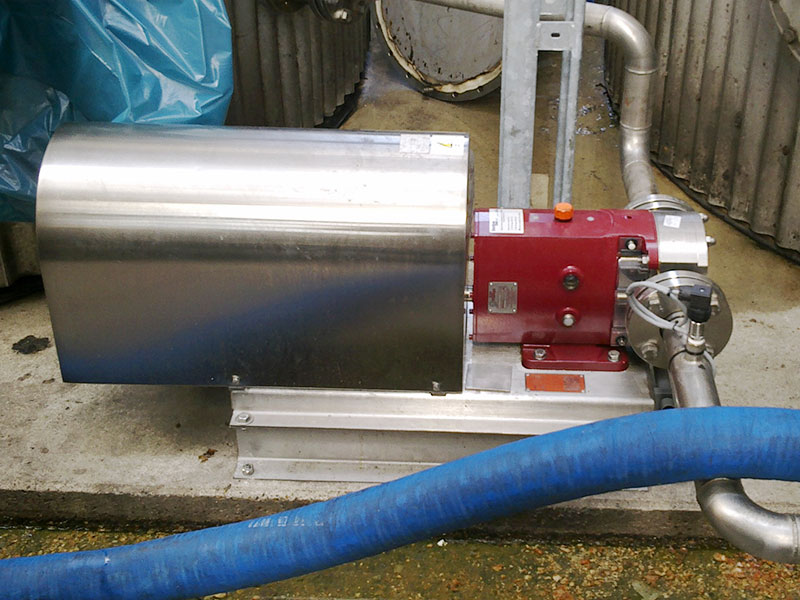

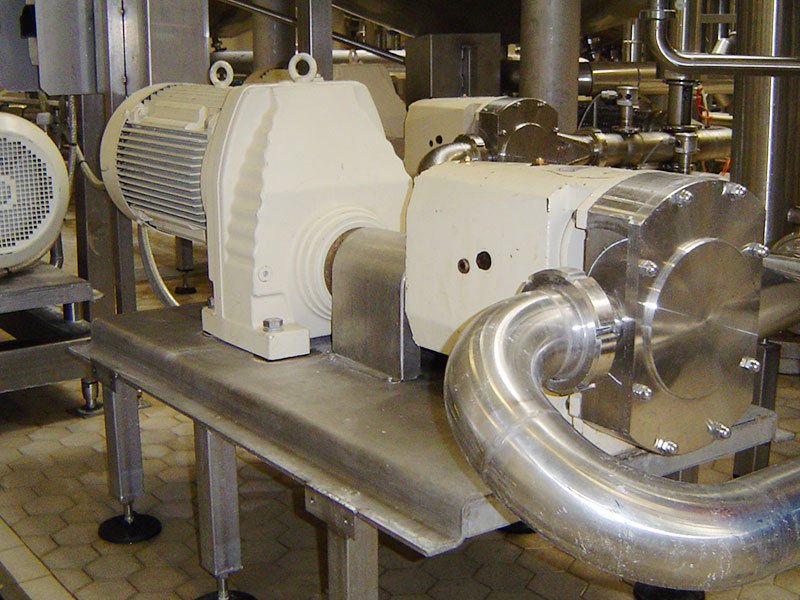

Stalowe pompy rotacyjne krzywkowe serii SSP charakteryzują się wysokiej jakości konstrukcją ze zoptymalizowanymi funkcjami jakości życia, aby zaoferować klientom maksymalną wydajność, niezawodność i wartość. Nadaje się do stosowania w różnych branżach na całym świecie, w tym w przemyśle farmaceutycznym, papierniczym i przesyłania płynów luzem, seria S spełnia wymagania nawet w najtrudniejszych warunkach, w tym CIP (czyszczenie na miejscu) i SIP (sterylizacja na miejscu).

All metallic pumped media components are manufactured in 316L type stainless steel. As standard, the Series S tri-lobe rotors are available in three temperature ratings, allowing the pump to be operated at maximum temperatures of 70˚C, 130˚C, and 200˚C for both process and CIP.

316L stainless steel shafts are used for pressures up to 10 bar. Higher pressures up to 20 bar are attained by the use of high strength duplex stainless steel.

Robust full stainless steel gearbox with a universal design enables flexibility of mounting pumps with the inlet and outlet ports in either a vertical or horizontal plane by changing the foot of its position, offering the flexibility to fit your infrastructure.

Series SRU liquid transfer pumps are classified for use in potentially explosive atmospheres under the ATEX Directive 2014/34/EU Group II, Categories 2 & 3, with temperature classification T2 and T4.

Series SRU pumps feature a modular design giving a huge choice of 44 models, providing greater application flexibility for customers and a cost-effective solution for every industry.

Series SRU fluid transfer pumps are extremely hygienic, earning a EHEDG accreditation and conforming to the USA 3A Sanitary Standard. They are also suitable for CIP and SIP.

The optimum seal can be chosen to match your pumped media requirements and duty conditions. Single or double mechanical seals are available and include flushed or aseptic variants. For arduous conditions, hard faced seal materials can be used. Plus, packed glands offer a simple, low cost, and easy to maintain controlled leakage sealing arrangement.

Energy efficient transfer of pumped media with minimal agitation due to the smooth flow and low shear pumping technology. The overall result is a transfer pump with low energy consumption and maximum performance.

The Series SRU pump range has twelve pump head displacements ranging from 0.053 litres / rev to 3.53 litres / rev.

Series SRU rotary lobe pumps are core rotary lobe pump and most comprehensive solution for all applications. They feature an extremely hardy and durable design, making them suited to all applications where reliable liquid transfer is needed.

The Series SRU has been engineered to provide a long service life offering efficient performance in a variety of industries including but not limited to paper, pharmaceuticals, and tank storage.

Our application know-how extends beyond designing and developing our products. We also provide a complete aftermarket service offering including access to our extensive network of service centres and engineers for all of our liquid transfer pumps. “We keep you moving” is more than just a strap line, it’s our promise. If you break down, we’ll get you into one of our dedicated local service centres and back on the road as soon as possible. To find out more about Gardner Denver Transport’s aftermarket portfolio, including our service kits, recommended maintenance intervals and localised support network, view our aftermarket capabilities homepage.