Select Your Country/Region

Current Region:

Poland (PL)

Poland (PL)

Choose a different country or region to see the content specific to your location

Current Region:

Poland (PL)

Poland (PL)

Choose a different country or region to see the content specific to your location

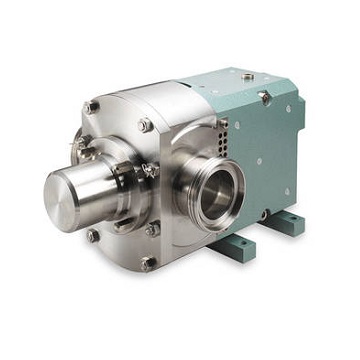

Rotacyjna pompa ładunkowa STP została specjalnie zaprojektowana do bezpiecznego i szybkiego rozładunku cystern i kontenerów. Konstrukcja pompy STP jest idealna do przenoszenia zarówno produktów spożywczych, jak i chemikaliów w szerokim zakresie lepkości, co czyni ją elastyczną i wszechstronną pompą odpowiednią do szerokiego zakresu celów i zastosowań.

Click the button below to instantly download our product flyer. Discover features, benefits, and much more at your own pace. It's the perfect way to get to know our product better.

STP pumps are available with a wide range of seal options. For foodstuffs (glucoses, fruit juice concentrates, butter oil, etc.) the optimum choice is the single O-ring seal, and for chemicals and solvents, a multiple lip seal arrangement is available. In addition, a range of mechanical seals are available where required. All seals can be fitted in the same pump geometry.

The design of the STP tri-lobe rotors and ports has been developed using Computational Fluid Dynamics techniques to provide a smooth, gentle pump characteristic which minimises agitation and degradation of the pumped media. This results in a quick and quiet discharge even with high viscous media.

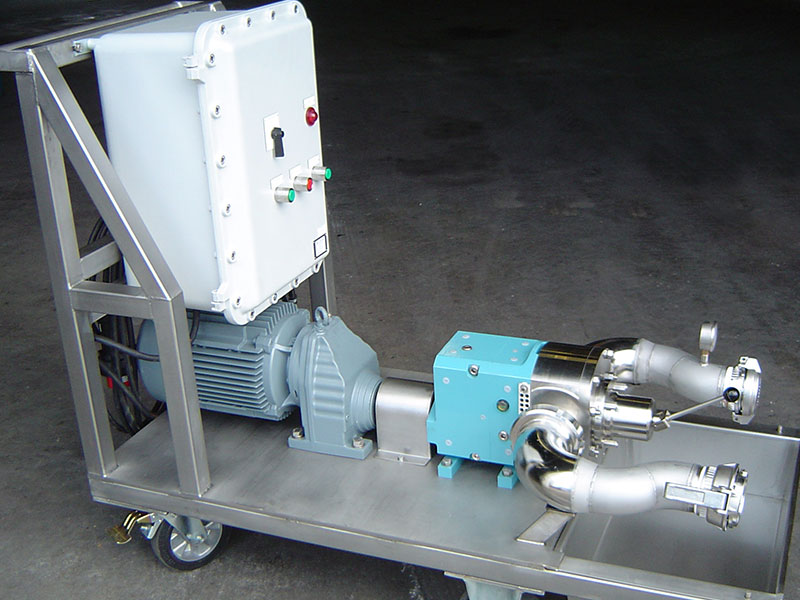

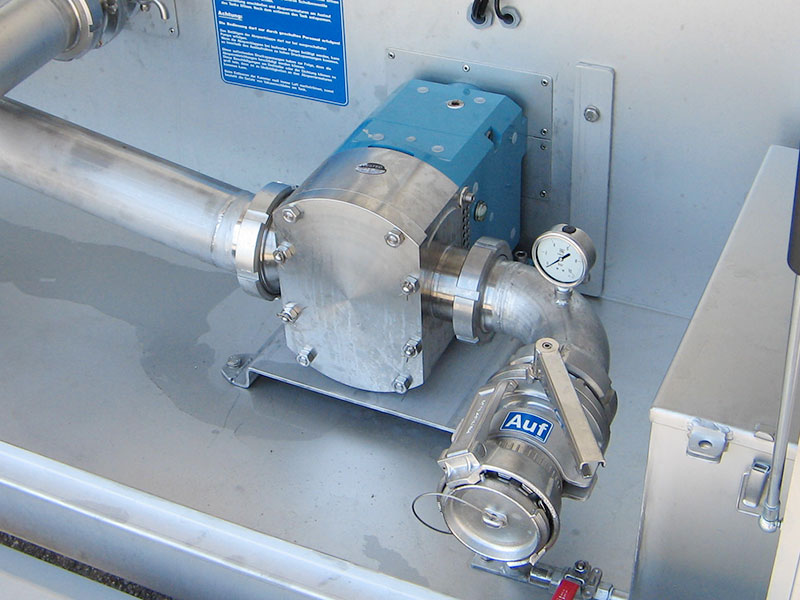

The compact build of the STP results in a minimum required space for mounting. The pump is designed for universal mounting with three sides of the gearbox pre-drilled to accept the mounting feet. Combined with a robust gearbox design, the STP pump can provide discharge pressure of up to 10 bar.

STP cargo pumps are equipped with an internal spline shaft to fit a close coupled hydraulic motor. A plain shaft extension with key is available as an option where a direct coupled electric, diesel, or PTO drive is required.

ATEX compliant version available to ensure safe handling of explosive material and hazardous chemicals.

The STP is suitable for CIP (Cleaning in Place) and SIP (Sterilisation in Place) and is certified to 3A and FDA standards, offering customers reliable and highly sanitary pumping conditions.

The STP pump design has been optimised specifically for applications within the road tank industry, providing low pulsation and low shear handling of sensitive products, reducing the risk of product damage and thereby improving product quality.

The rotor case can be inverted, where required, adding flexibility to the port arrangement.

On request the pump can be supplied with sealed heating tanks for safe and reliable handling of delicate, temperature sensitive products.

The STP pump’s advanced technology and engineering provides smooth flow, reversible operation that is reliable and efficient.

The STP compact pump build combined with a robust gearbox design provides for discharge pressure of 10 bar and for temperatures up to 70˚C (or at 130˚C for CIP/SIP).

STP stainless steel rotary lobe cargo pumps have been specifically designed for applications within the liquid transfer industry for road tankers. Suitable for handling a wide variety of liquid types, STP pumps provide hygienic performance for:

Gardner Denver Transport provide a complete aftermarket service offering including access to our extensive network of service centres and engineers for all of our fluid transfer pumps. “We keep you moving” is more than just a strap line, it’s our promise. If you break down, we’ll get you into one of our dedicated local service centres and back on the road as soon as possible. To find out more about Gardner Denver Transport’s aftermarket portfolio, including our service kits, recommended maintenance intervals and localised support network, view our aftermarket capabilities homepage.